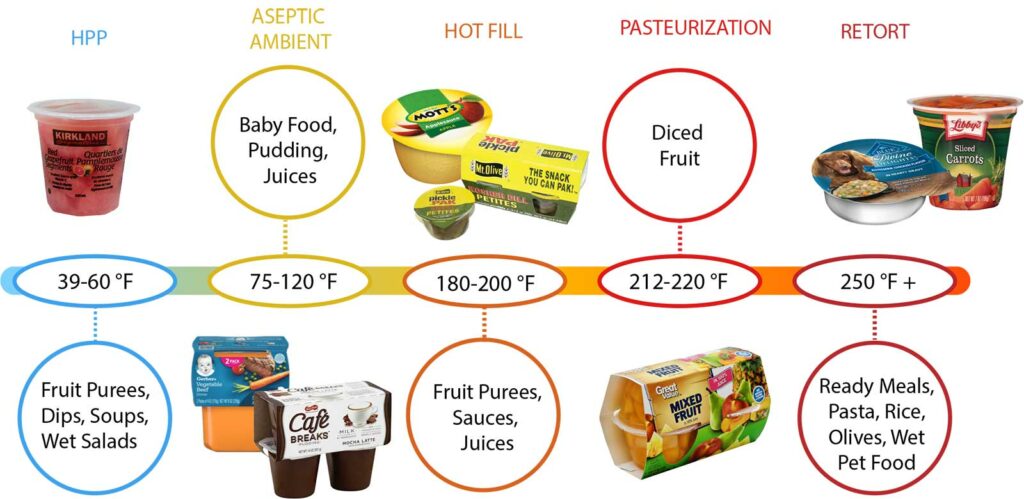

Depending on the type of food and processing method, as well as the product’s storage conditions, we can help you achieve a shelf life of up to two years or more.

With new sustainable packaging ideas being dreamed up every day, brands that work with manufacturers that have in-house testing capabilities such as us can be the first to bring these new technologies to market. For example, with a combination of top-of-the-line machinery and industry experts, our pilot plant is used to explore new materials, perform fast-paced experimentation, and offer prototypes – all while product protection for your brand is realized. Read how our industry-leading innovative research, pilot plant, and analytical lab bring an edge to the future in packaging.