Packaging Formats

We offer customizable products that set the bar for snack product freshness, graphic appeal, in a full range of formats — including form fill seal (VFFS) packaging, preformed bags and pouches, bar wraps, and more.

Bar Wrap

• High-impact graphics

• Surface finishes include matte, gloss, embossed, and many more

• Clear barrier options available for product visibility

• Cold seal films which require no heat

Cups

• Preformed cups for salty snacks

• Customizable barrier properties to meet your product’s needs

• Stock or customized design options for preformed cups

• On-the-go designs provides portability and convenience

Pillow Pouch

• Pillow pouches are the most frequently used pouch forms

• Various sizes available

• Pillow pouch has a top seal, bottom seal, and a back seal

• Add metallic coating to protect your product from moisture, oxygen, and light for a longer shelf life

Rollstock

• High-impact graphics

• Print finishes include matte and gloss

• Premium clear high gloss options for retail

• Multiple structure options available

• Focused factory and customer service for ream wrap production

• Internal graphic services

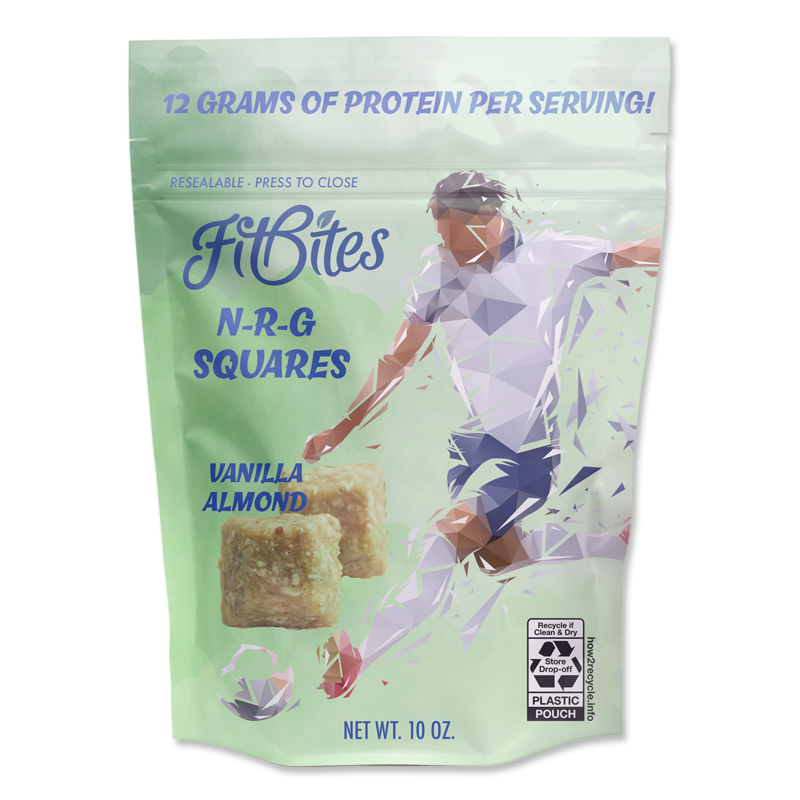

Stand-Up Pouch

• Custom engineered films and rollstock for form, fill, and seal applications

• Pre-made pouches and bags with a wide variety of features available (shapes, spouts, easy open, re-close, etc.)

• Structures for any application including hot-fill aseptic and retort

• Available in multiple styles, including Doyen

Sustainable Packaging Film Portfolio

Meet our full Preserve™ family of sustainable snack packaging, featuring recyclable and compostable packaging solutions as well as others made from post-consumer recycled materials and a variety of renewable sources.

Preserve™ Circular/Renewable

• Offsets virgin plastic to meet corporate goals and regulatory requirements for virgin plastic reduction

• Lowers packaging carbon footprint

• Use of content made from recycled plastics creates demand for plastics circularity

• Source of content include post-consumer and post-industrial plastics that are mechanically recycled

• Source of content include post-consumer and post-industrial plastics that are recycled by advanced recycling processes, such as pyrolysis (known as “Certified Circular Content”)

• Plastics made from renewable feedstock sources such as used cooking oil (UCO) and technical corn oil (TCO) (known as “Certified Renewable Content”)

• Options available for PE, PP, and PET

• Use of Certified Circular and Certified Renewable content requires no packaging formulation changes, and there is no regulatory or food safety risk because the plastic material is chemically indiscernible from virgin plastic

Preserve™ Compostable

• Made with pre-certified industrial compostable films, inks, and adhesives

• Package integrity – strong, airtight seals – seals through contamination, excellent flavor, aroma, and grease barrier properties

• Environmentally-friendly packaging – lower your packaging carbon footprint

• Sustainable – manufactured from a renewable material source

• Matte (OPV) option is available

• PVdC-free packaging

• HFFS and VFFS flexible packaging formats

Preserve™ Recyclable Fiber

• Passed Western Michigan University testing protocols for repulpability and recyclability

• Sustainable solution designed for the curbside recycling stream

• Economical packaging solution for products that do not require high moisture and oxygen barrier

• Pre-made pouches/bags

• HFFS flexible packaging

• VFFS flexible packaging

Preserve™ Recyclable PE

• Recyclable through the How2Recycle Store Drop-off program

• Meets the same food safety standard as conventional high density polyethylene

• Standard and high barrier options available

• Pre-made pouches/bags

• HFFS flexible packaging

• VFFS flexible packaging

With more than 60 years of experience, Printpack understands the critical role packaging plays in the buying decisions of today’s consumers.

With more than 60 years of experience, Printpack understands the critical role packaging plays in the buying decisions of today’s consumers.